Detection and surveillance

Detection & Monitoring ATEX:

Solutions for explosive zones

In industrial facilities where explosive atmospheres are possible, the ATEX detection is an indispensable security pillar.

The solutions of Detection & monitoring ATEX Let's identify early gas leaks, flames or critical conditions, ensuring the protection of staff, safeguarding equipment and compliance with current standards.

In A2sWe design certified, robust and modular systems to cover all your industrial needs in classified areas.

Our customers

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Previous

Next

Applications & Sectors

.jpg)

.jpg)

.jpg)

Oil & Gas / Refineries

Chemical & Petrochemical Industry

Gas treatment / GPL stations

.jpg)

.jpg)

.jpg)

Pharmaceutical & Agri-Food

Marine / Offshore Environments

Critical facilities

Services & Accompaniment

Site Audit & ATEX Zone Study

Development of specifications

Installation, compliance, calibration

Periodic maintenance, support & updates

ATEX / Safety Standards Training in Explosive Environments

Advantages of A2S solutions

Certified ATEX / IECEX / EN

Modular design, scalable

Optimized King

Full Service (Audit, Installation, Calibration, Maintenance)

Technical support and expert service

FAQ

Early detection To anticipate the dangers

Regulatory compliance (ATEX Directive 2014/34 / EU, IECEX standards)

Maintenance of business continuity and reduction of stops

Safety of people, goods and the environment

Definition of gas zones (0/1/2) and dust (20/21 / 22)

Requirements of Selection of equipment According to categories

Associated standards (EN, IECEX, ATEX) and marking

Modes of protection (Ex d, ex, ex i, ex p, etc.)

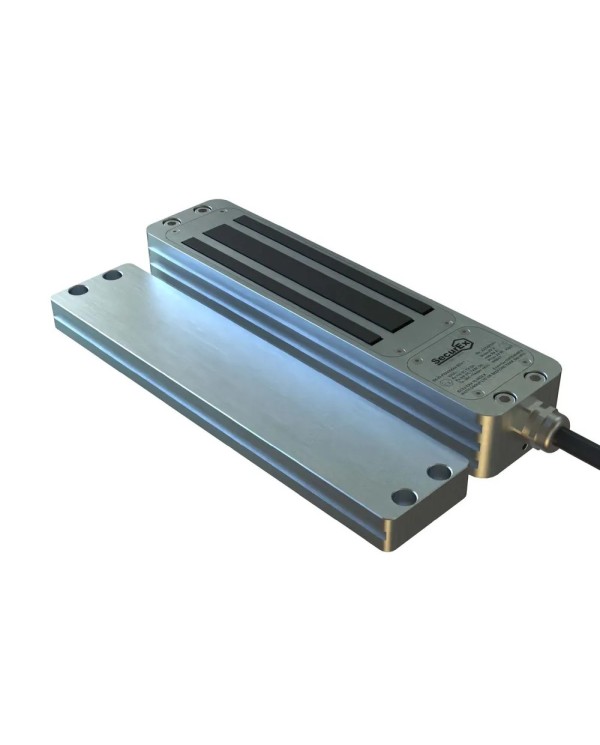

1. Gas detectors

- Principles (electrochemical, catalytic, infrared, pellistor, etc.)

- Targeted gases (CH4, H2S, CO, CO2, etc.)

- Fixed sensors VS Portable

- Criteria of choice (answer, sensitivity, response time)

2. Flame detectors

- UV, IR, UV / IR sensors

- Typical applications (flammable gas leaks, fires)

- Time of detection, immunity with false alerts

3. Multi-sensor detectors & handsets

- Smoke + heat, optical + thermal

- Advantages in complex environments

4. Other sensors / techniques

- Thermal / thermovelocimetric detectors

- Aspirations, Vesda systems

- Optical fiber detection (if applicable)

The choice of ATEX detector Depends on the type of gas to monitor and site conditions.

For the combustible gases (methane, propane, butane ...), we often use catalytic sensors or Infrared (IR).

For the toxic gases like CO, H₂S, nh₃, the electrochemical sensors are the most adapted.

The Photo-ionization detectors (PID) Suitable for volatile organic compounds (VOCs).

The choice is also done according to the ATEX zone (0, 1, 2/20, 21, 22) and certification requirements.

A2S experts can help you define the safest technology and in accordance with your industrial environment.

A ATEX detector must be maintained regularly To guarantee its reliability:

Visual inspection and periodic cleaning of the sensor.

Calibration and Response Test Target gas (every 6 to 12 months depending on the conditions).

Replacing detection cells at the end of life.

One Preventive maintenance plan Ensures compliance with ATEX standards and extends the life of the equipment.

A2S offers Maintenance contracts and on-site calibration For all his models.

These classifications define the level of risk of explosion due to the presence of gas:

Zone 1: the risk is likely During normal operation (occasional presence of explosive gas).

Zone 2: the risk is rare and short-term, usually during an incident or accidental leak.

The equipment installed in these areas must be Certified ATEX and designed to avoid any source of inflammation (sparks, warm-up, electrostatic discharge ...).

The service life depends on the Technology used :

Electrochemical : 2 to 5 years depending on gas and ambient conditions.

Catalytic : About 3 to 5 years.

Infrared (IR) : up to 10 years with adapted maintenance.

Dusty, wet or corrosive environments can reduce longevity.

One Maintenance and Recalibration Program Regular is essential to maintain accuracy and compliance.

ATEX compliance is valid according to the European Directive 2014/34 / EU, which frames the manufacture and use of equipment for explosive areas.

To be consistent, you need:

Use Certified ATEX / IECEX Certified Hardware corresponding to the installation area.

Dispose of CE CE examination certificate and a ATEX marking Clear (eg Ex d IIC T6 GB).

Make a Compliance assessment of the installation by a competent body.

Keep the technical documentation and periodic inspection reports.

A2S accompanies its customers in the Validation and traceability equipment to ensure sustainable security and compliance.

Do you want to secure your site in ATEX zone or get a personalized audit?

Contact our experts today For a free study or a quote within 24-48h.

FILTERS

Showing 1-30 of 57 item(s)

.jpg)

.jpg)

.jpg)

![Conventional Flame Detector (IR3) [SIL2] | A2S](https://www.a2s-atex.com/14-medium_default/conventional-flame-detector-ir3-sil2-.jpg)