Data sheet

Data sheet

- IP55

- Tubular ferrule made of steel sheet.

- Polyamide 6 propeller reinforced glass fiber.

- Protective grid against contacts according to the standard one-en ISO 12499, on both sides.

- Hand retrofit power switch connection box. To avoid accidental startup (ES-ISO 12100).

- Air-propeller direction.

- The fan switch is coupled to a CESTAC P17 plug. For three-phase motor: 3P + T 16A. For single-phase motor: 2P + T 16A.

- Engines with IE3 yield for powers equal to or greater than 0.75 kW, except single-phase, 2 speeds and 8 poles.

- Class F motors with ball bearings and IP55 protection. Except monofásicos models of size 35 to size 56, with IP54 protection.

- single phase 230 V 50 Hz and three-phase 230/400 V 50 Hz.

- Operating temperature: -25 ºC +50 ºC.

These mobile tubular helicoid fans are designed to provide efficient and flexible ventilation in various applications. Thanks to their robust tubular structure, they guarantee great strength and increased durability. The mobility of these fans makes it easy to move them as needed, providing a practical solution for ventilating different spaces. Their design ensures optimal performance while being tailored to demanding environments.

Data sheet

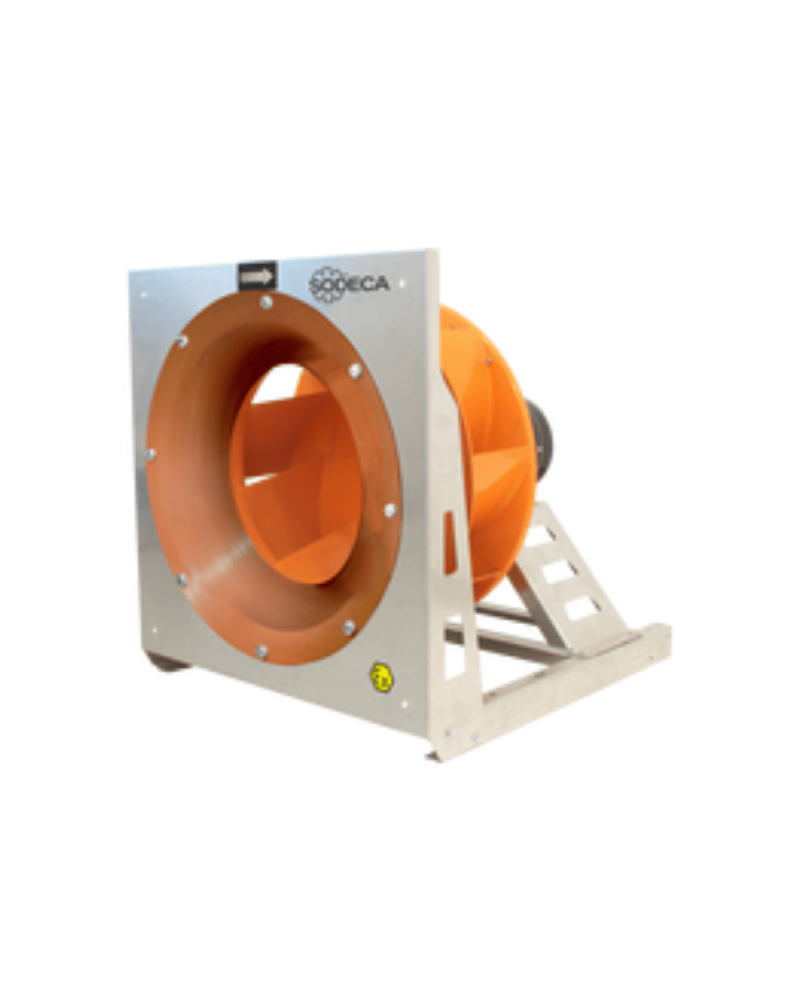

- Profiled structure in aluminum.

- Covers with insulating acoustic envelope of 25 mm, high quality, in sheet metal.

- Reaction turbine.

- Standard flanges in suction and pulse, to facilitate installation in the ducts.

- Interchangeable lids to contain the impulse of any side.

- Air inlet mouth with diffusers for more fan efficiency.

- Silentblocks to avoid the transmission of vibrations and a correct anchor of the equipment.

- Copper anti-sparking aspiration ring.

- Aluminum corners to prevent static accumulation.

- Maximum air temperature to be transported: -25 ºC +88 ºC (T4) or +120 ºC (T3).

- Standard marking with explosion engine (ex dB): II 2g Ex H iB T4 GB.

- Standard marking with increased safety motor (ex eB): II 2G ex H iB T3 GB.

- Standard marking with dust motor (ex tb): II 2D Ex H IIIC T135 ºC dB.

- CLASS F motors with ball bearings and ATEX anti-ddflagrant certificate, increased safety ex eb or virole protection for ex tb.

- Engines with integrated PTC.

- Three-phase 230/400 V 50 Hz.

- Operating temperature: -20 ºC +40 ºC.

The CJPF / ATEX ventilation units are designed to provide high air flow with maximum efficiency, thanks to their plug fan technology. ATEX 2G or 2D certified, they are suitable for use in potentially explosive environments, whether in the presence of gas (2g) or dust (2D). They can be equipped with different types of engines according to the specific safety requirements.

Data sheet

- Galvanized steel sheet support base and anticorostive treatment.

- Polyamide 6 propeller reinforced with fiberglass, except models 100 and 4 aluminum poles.

- Grid of protection against birds.

- Painted galvanized sheet steel shoe hat with anticorrosive protection.

- Air-propeller direction.

- Engines with IE3 yield for powers equal to or greater than 0.75 kW, except single-phase, 2 speeds and 8 poles.

- single phase 230 V 50 Hz and three-phase 230/400 V 50 Hz (≤ 4 kW) and 400/690 V 50 Hz (> 4 kW).

- Operating temperature: -25 ºC +60 ºC.

These helical roof extractors are designed with a flat base, facilitating their installation on various types of roofs. Their helical design allows efficient air extraction, improving ventilation and air circulation in the underlying spaces. The flat base provides stable and secure attachment, minimizing the risk of air leakage and ensure optimum performance.

Data sheet

- Aluminum cast iron helix.

- Air-propeller direction.

- Anti-teddy cable gland included.

- Steel sheet support frame, with aluminum strip in the helix area according to EN 14986.

- Anti-contact protection grid according to the standard one-en ISO 12499.

- Standard marking with explosion engine (ex dB): II 2g ex h iB + H2 T4 GB.

These helical wall mounted extractors are designed with a square frame and are certified according to the ATEX II 2G standard, ensuring their safety in potentially explosive environments. They are equipped with ex dB engines, specially designed to prevent any ignition in dangerous atmospheres. These extractors are particularly suitable for use in environments where hydrogen is present, offering a reliable and secure solution for air and gas extraction.

Data sheet

- Galvanized steel sheet support base and anticorostive treatment.

- Adjustable throttle propellers of cast aluminum.

- Anti-contact protection grid according to the standard one-en ISO 12499.

- Hat deflector rainworm made of painted galvanized steel sheet, with natural air outlet.

- Standard marking with explosion engine (ex dB): II 2g Ex H iB T4 GB.

- Standard marking with increased safety motor (ex eB): II 2G ex H iB T3 GB.

- Standard marking with dust motor (ex tb): II 2D Ex H IIIC T135 ºC dB.

- CLASS F motors with ball bearings and ATEX anti-ddflagrant certificate, increased safety ex eb or virole protection for ex tb.

- single phase 230 V 50 Hz and three-phase 230/400 V 50 Hz (≤ 4 kW) and 400/690 V 50 Hz (> 4 kW).

- Operating temperature: -20 ºC +40 ºC.

These multifunctional turrets are designed to handle large air flows, making them ideal for applications requiring intensive ventilation. They are ATEX 2G or 2D certified, ensuring their compliance for use in potentially explosive environments, whether in the presence of gas (2G) or dust (2D). These turrets are equipped with specialized engines, available in several variants to meet specific security requirements

Data sheet

- Structure in reinforced steel sheet.

- Reaction turbine, steel sheet.

- with pressure test for automatic flow control.

- Vertical execution not available for sizes 1871 and 2180.

- A frequency converter is required for workpoints requiring regimes other than nominal engine.

- IE3 efficiency AC motors.

- Class F motors with ball bearings and IP55 protection.

- Three-phase 230/400 V (≤ 4 kW) and 400/690 V (> 4 kW).

- Maximum air temperature to be transported: -25 ºC +60 ºC.

These high-efficiency Centrifugal Type Fan fans are specially designed for air processing applications. They incorporate an AC engine that offers reliable and efficient performance. Their Fan plug-type design optimizes energy efficiency and ensures high air flow all in particular charge losses. Ideal for ventilation and air conditioning systems, these fans offer optimal air management in various environments, while providing simplified maintenance and increased durability.

Data sheet

- Aluminum cast iron helix.

- Air-propeller direction.

- Anti-teddy cable gland included.

- Steel sheet suction ring with aluminum strip on the helix area according to EN 14986.

- Standard marking with explosion engine (ex dB): II 2g ex h iB + H2 T4 GB.

These helical extractors are designed with a circular framework and have ATEX II 2G certification, ensuring their safety for use in explosive atmospheres. Equipped with ex dB engines, they offer enhanced protection against the risk of inflammation in hazardous environments. These extractors are specially adapted for use with hydrogen, ensuring efficient and secure ventilation under potentially risky conditions.

Data sheet

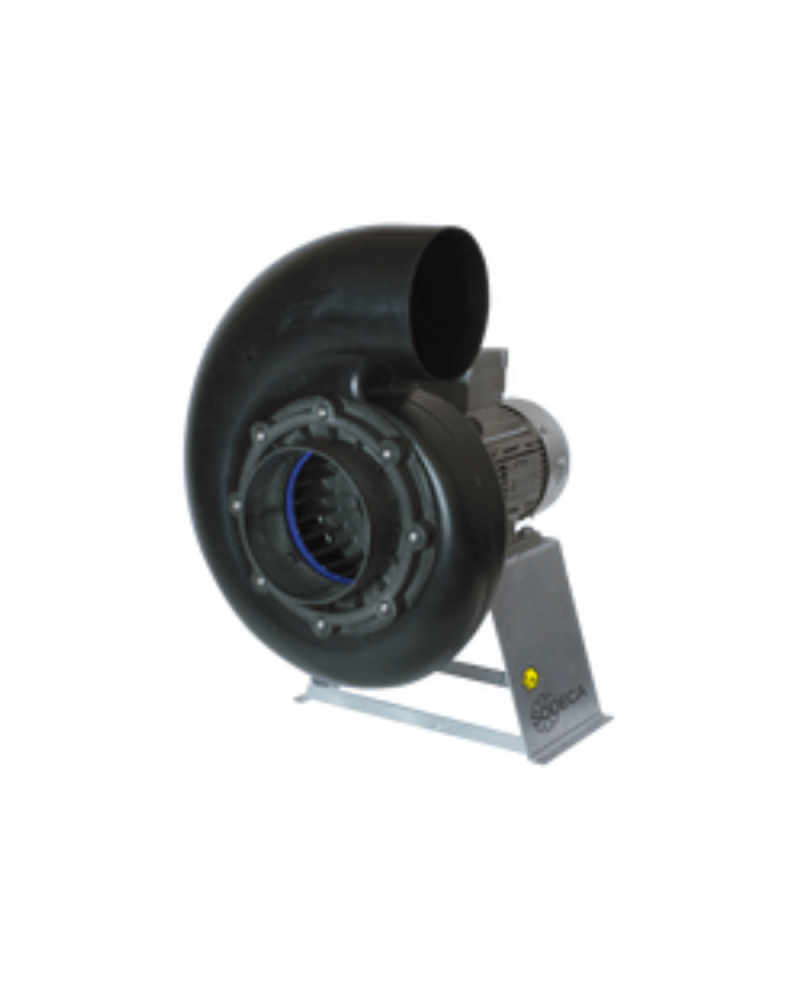

- Polypropylene ferrule.

- Turbine with action, polypropylene.

- Maximum air temperature to be transported: -25 ºC +70 ºC.

- Engines with IE3 yield for powers equal to or greater than 0.75 kW, except single-phase, 2 speeds and 8 poles.

- Class F motors with ball bearings and IP55 protection.

- Three-phase 230/400 V 50 Hz (≤ 4 kW) and 400/690 V 50 Hz (> 4 kW).

- Operating temperature: -20 ºC +70 ºC.

These anticorrosive centrifugal fans, with one hearing, are made of polypropylene, a material recognized for its exceptional resistance to corrosion. This construction makes them particularly suitable for environments where conditions can be corrosive, ensuring a long service life and reliable performance. Their centrifugal design provides efficient ventilation, while their polypropylene structure minimizes the risk of wear and damage caused by corrosive substances. These fans are ideal for industrial or commercial applications where corrosion resistance is essential.

Data sheet

- IP54

- Steel sheet support frame.

- Polyamide 6 propeller reinforced glass fiber.

- Anti-contact protection grid according to the standard one-en ISO 12499.

- Models 71, 80, 90 and 100: The protective grid is provided as an accessory.

- Air-propeller direction.

- Operating temperature: -20 ºC +60 ºC.

These wall-mounted helicoid fans are equipped with a fiberglass reinforced plastic propeller. This reinforcement ensures great durability and increased resistance, even under demanding conditions of use. Ideal for applications requiring efficient and reliable ventilation, these fans offer optimal performance while being robust and durable.

Data sheet

Data sheet

- Ferrule of cast aluminum.

- Aluminum cast iron turbine.

- Models 324, 325 and 426 Polyamide turbine, model 531-2T-3 Turbine made of sheet steel.

- Maximum air temperature to be transported: -25 ºC + 120 ºC, maximum +70 ºC The models with poliamide turbine.

- Engines with IE3 yield for powers equal to or greater than 0.75 kW, except single-phase, 2 speeds and 8 poles.

- single phase 230 V 50 Hz and three-phase 230/400 V 50 Hz.

These medium pressure centrifugal fans are designed for simple aspiration and have a ferrule and an aluminum cast iron turbine. Their cast aluminum construction ensures both robustness and lightness, while offering excellent wear resistance and varied operating conditions. Centrifugal design allows efficient air management, while the ferrule optimizes the flow and ventilation pressure. Ideal for applications requiring moderate pressure and effective aspiration, these fans combine durability and performance.

Data sheet

- Air-propeller direction.

- POL version PL in polyamide 6 reinforced with fiberglass and aluminum cast iron version. The HCT-40-2T model exists only in Al.

- Steel sheet support ring.

- Engines with IE3 yield for powers equal to or greater than 0.75 kW, except single-phase, 2 speeds and 8 poles.

- Class F motors with ball bearings and IP55 protection. Except Monofásicos models of size 45 to size 56, with IP54 protection. 1 ó 2 speeds depending on model.

- single phase 230 V 50 Hz and three-phase 230/400 V 50 Hz (≤ 4 kW) and 400/690 V 50 Hz (> 4 kW).

- Operating temperature: -25 ºC +50 ºC.

These wall-mounted helicoid fans are designed to provide great solidity and durability. Ideal for demanding environments, they are made with robust materials that provide reliable performance and long service life. Their solid design makes it possible to support intensive conditions of use, ensuring efficient ventilation and resistance to mechanical and environmental constraints.

Data sheet

Data sheet

- Steel sheet steel, except models 38-2m and 380 cast aluminum.

- Action turbine with reinforced steel sheet.

- Maximum air temperature to be transported: -25 ºC + 120 ºC, maximum +100 ºC models 38-2m and 380.

- Engines with IE3 yield for powers equal to or greater than 0.75 kW, except single-phase, 2 speeds and 8 poles.

- Class F motors with ball bearings and IP55 protection. Except monofásicos models with IP54 protection. 38-2M and 380 models with IP21 protection.

- single phase 230 V 50 Hz and three-phase 230/400 V 50 Hz (≤ 4 kW) and 400/690 V 50 Hz (> 4 kW).

- Operating temperature: -25 ºC +50 ºC.

These medium pressure centrifugal fans, with simple suction, are equipped with a ferrule and a sheet steel turbine. The steel sheet is used for its robustness and resistance to difficult work environments, ensuring a long service life and stable performance. The simple suction design allows an efficient airflow, while the ferrule optimizes the distribution of air and pressure. These fans are particularly suitable for industrial applications where reliable medium-pressure ventilation is required, while providing durable and resistant construction.

Data sheet

- IP54

- Air-propeller direction.

- POL version PL in polyamide 6 reinforced with fiberglass and aluminum cast iron version. The 40-2T and 45-2T models exist only in Al.

- Tubular shell made of sheet steel with outdoor terminal box.

- Engines with IE3 yield for powers equal to or greater than 0.75 kW, except single-phase, 2 speeds and 8 poles.

- Class F motors with ball bearings and IP55 protection. Except Monofásicos models of size 45 to size 56, with IP54 protection. 1 ó 2 speeds depending on model.

- single phase 230 V 50 Hz and three-phase 230/400 V 50 Hz (≤ 4 kW) and 400/690 V 50 Hz (> 4 kW).

- Operating temperature: -25 ºC +50 ºC.

These tubular helical fans are designed to provide high strength and durability. Designed for use in demanding environments, they are manufactured with robust materials that provide reliable performance and long service life. Their tubular construction reinforces their structure, to support intensive conditions of use while ensuring effective ventilation.

Data sheet

Data sheet

- Sheet steel ferrule.

- Turbine with reaction, made of high robustness steel sheet.

- Copper anti-sparking aspiration ring.

- Maximum air temperature to be transported: -25 ºC +88 ºC (T4) or +120 ºC (T3).

- Standard marking with explosion engine (ex dB): II 2g Ex H iB T4 GB.

- Standard marking with increased safety motor (ex eB): II 2G ex H iB T3 GB.

- Standard marking with dust motor (ex tb): II 2D Ex H IIIC T135 ºC dB.

- Class F motors with ball bearings. ATEX Anti-Flavaging Certificate Ex DB, Increased Safety Ex Eb or Dust Ex TB.

- Three-phase 230/400 V 50 Hz (≤ 4 kW) and 400/690 V 50 Hz (> 4 kW).

- Operating temperature: -20 ºC +40 ºC.

These medium pressure centrifugal extractors are equipped with reaction turbines designed to provide optimal performance in demanding environments. Certified according to ATEX 2G or 2D standards, they are specially adapted for use in areas at risk of explosion, whether gas (G) or dust (d). The engines available for these extractors can be of type ex dB, ex eb or ex tb, each offering protection against explosions.

Data sheet

- Tubular ferrule with rotating hatch. Sheet steel.

- Aluminum cast iron helix.

- Group with bearings and cast iron support.

- Air transmission-propeller direction.

- Air temperature to be transported: -25 ºC to +120 ºC.

- Engines with IE3 yield for powers equal to or greater than 0.75 kW, except single-phase, 2 speeds and 8 poles.

- Class F motors with ball bearings. IP55 protection.

- single phase 230 V 50 Hz and three-phase 230/400 V 50 Hz (≤ 4 kW) and 400/690 V 50 Hz (> 4 kW).

These tubular helical fans are equipped with an external engine, which offers several advantages. The external position of the engine facilitates its access for maintenance and reduces exposure to internal conditions, increasing its durability and reliability. This design also allows better heat dissipation and more efficient operation. Fans are ideal for applications requiring powerful and constant ventilation, while ensuring easy maintenance and long service life

Data sheet

Data sheet

Data sheet